May 13, 2022

Why do earthquake strengthening work on a barn?

One of the most common and most important precast structures on a farm is the barn.

A barn is a building generally made up of precast modules in prestressed reinforced concrete or, sometimes, in steel, designed for agricultural use.

What is it used for? It has many uses, for example protecting machinery when not in use and storing products and everyday materials. In some cases, it also serves as a livestock shed, sheltering the farm’s animals from the elements.

This type of building is a valuable aid to medium- and large-scale farms.

To circumvent the lengthy building times associated with brick structures, over the last few decades the industrial building sector has introduced so-called precast concrete buildings. These industrial structures are erected using standard reinforced concrete, iron or masonry modules, which significantly reduce the time required to install the building on site. Alternatively, steel panels (so-called sandwich panels) can be used in place of concrete, greatly improving thermal and sound insulation, producing a protected and insulated interior. Generally speaking, precast structures require a relatively small financial investment, while the bureaucratic issue of permits and managing environmental impact remain the same.

With a number of companies specialized in their production and assembly, farmers can save time and money by receiving a custom-made barn or shed that is ready for use straight away.

However, buildings erected prior to 2008 have often not been designed and produced to the latest and safest earthquake standards.

These structures are more exposed to potential earthquake damage, with risks varying depending on what techniques have been used in the fabrication of the building in question and what seismic risk area it has been built in.

Potential damage can range from deterioration of facades and simple cracks in walls to partial or even total structural collapse, seriously endangering people, livestock, machinery, products or anything else contained in the building.

Seriana’s agricultural project sites

Over the course of our experience, which has made us a leading name in the earthquake strengthening industry, we have worked on a number of buildings in the agricultural sector to improve their earthquake resilience. Two cases in point are Latteria Sociale Roverbella and Bio Alleva.

Learn more about earthquake strengthening.

Latteria Sociale Roverbella

A dairy cooperative located in Roverbella in the province of Mantua, producing wheels of grana padano cheese, handling all stages of production: from curdling to soaking in brine, through to ageing and ultimately its sale.

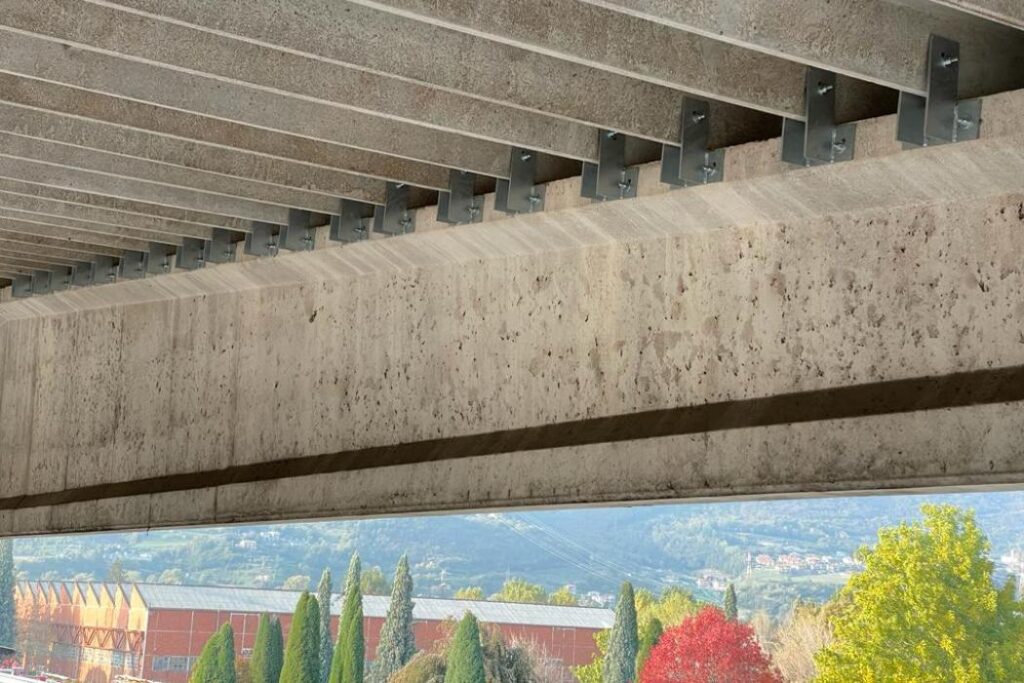

The building’s cramped spaces saw our highly specialized teams working, albeit safely, on scaffolding barely 60 centimetres wide to perform fastening and strengthening work on roof beams, beams and columns.

Water-cooled coring operations were carried out, namely holes were made to accommodate the reinforcements without generating dust that might otherwise end up on food-grade equipment.

To secure the roof beams, they installed parapets around the building and created a stair tower to access the roof. They cut the roof membrane to install the fastenings, and then sewed it back up.

Bio Alleva

Bio Alleva is a farm located in the province of Verona and is in the business of producing certified organically farmed meat and salami, which it then distributes across Italy and overseas for use in Ho.Re.Ca. channels, industry, specialized retail chains and catering.

This project site involved the company’s whole structure, with a series of local strengthening measures consisting in strengthening beam-column and beam-roof beam connections and securing the panels making up the structure.

In addition, our teams used mezzanine platforms as the work was performed while one of the buildings was being renovated.

The building in question had a floor area of around 4,000 sq metres, with a team of four working on its completion within a month-long time frame.

Seriana creates solutions tailored to each project site, adapting to accommodate the production cycle and structural requirements of each company requesting the work.

The Seriana S.p.A. team will be happy to advise you, contact us today!