June 29, 2019

Research and Development: in-house testing for ever-improved earthquake strengthening work

At Seriana S.p.A., the R&D chapter never closes and is constantly geared towards innovation, in terms of practical experimentation as well as design and the software used. We have a wealth of technical assets on our team, comprising both engineers and surveyors, whose daily focus is building earthquake resilience.

In this article, we will be talking about the frequent testing sessions we have here, invariable working in synergy with prestigious international partners, such as Hilti. When it comes to designing earthquake-proofing measures, a very rational approach is required based on calculations: calculations that are backed up by specification sheets for each of the components used.

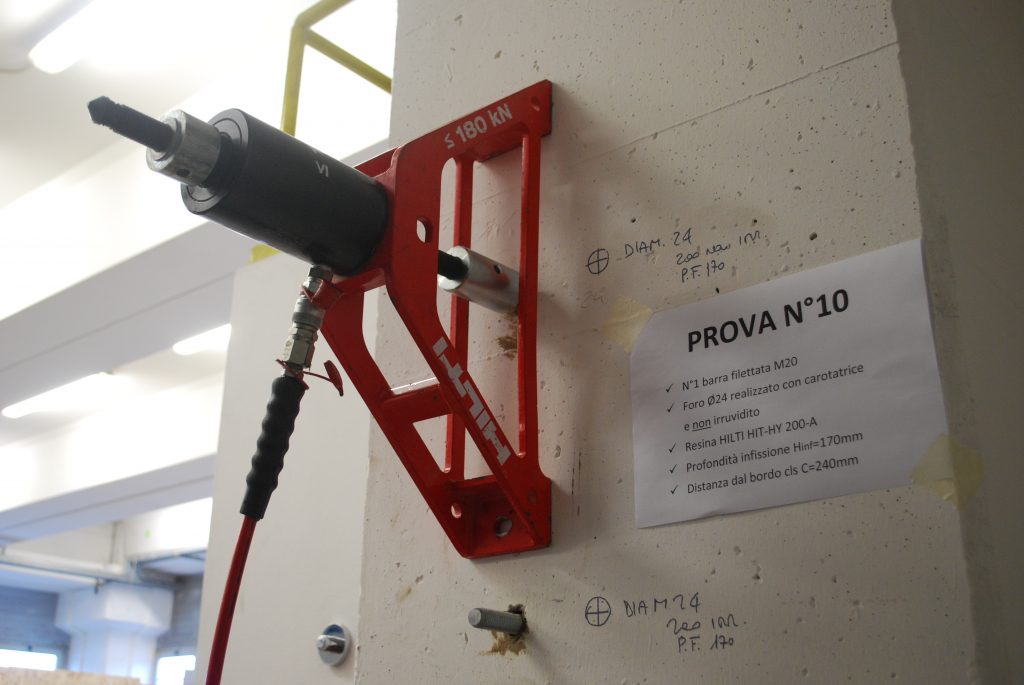

To ensure our designs are increasingly in line with the actual reality of the installation work, we fit plates and anchors with specific resins so as to see and measure their real-life behaviour. On a typical day, our workers, coordinated by our technical staff, fit the fastenings due to be tested to precast columns.

Specific numbering is associated with each test, with an accurate summary of the components employed. Hilti personnel come to Seriana on the arranged day and, once the pull-out resistance and tensile strength tester (Hilti HAT28) has been installed, the plates are subjected to the load and strain and pull-out tests performed on anchors and bars secured with resin. As soon as the strain gauge reaches levels close to breaking and initial micro-movements are detected, the test is stopped and can be deemed completed.

Our partner issues us with a report on everything that has been done and, based on the findings, we can draw up technical tables produced not just specifically based on the requirements of the client company’s building, but exemplary in engineering terms, too.